March 30, 2025

- Engines are the fundamental source of power for every vehicle, driving its performance and dependability. The inline engine, characterized by its straightforward and effective design, is among the most prevalent varieties seen in cars and motorcycles. It is recognized for its fuel efficiency and smooth functionality. Regular maintenance is crucial for extending the engine’s lifespan and ensuring peak vehicle performance.

- Incorporating an engine protection cover in your comprehensive car insurance provides financial coverage in the event of repairs or replacements for the inline engine.

What is InLine Engine?

An inline engine, commonly known as a straight engine, is a specific type of internal combustion engine. Its cylinders are arranged in a single straight line along the crankshaft. This configuration can be vertical, horizontal, or tilted, allowing adaptability in different vehicle designs. Because of its uncomplicated structure, the inline engine is a frequent selection in compact cars, motorcycles, and even certain trucks.

How Do Inline Engines Work?

Inline engines operate via a four-stroke combustion cycle: intake, compression, power, and exhaust. Here’s how each stroke operates:

- Intake Stroke:

The piston moves downwards, creating a vacuum that pulls a blend of air and fuel into the cylinder. This phase prepares the engine for combustion. - Compression Stroke:

The piston moves upwards, compressing the air-fuel mixture into a reduced space. This compression increases the mixture’s potential energy, making it ready for ignition. - Power Stroke:

A spark plug ignites, setting off the compressed air-fuel mixture. This results in an explosion, driving the piston downward and producing the power needed to move the vehicle. - Exhaust Stroke:

The piston rises again, ejecting the spent gases from the cylinder through the exhaust valve. This clears the chamber for the subsequent cycle.

These four strokes occur in a seamless sequence, ensuring smooth and effective engine performance. The coordinated movement of the pistons drives the crankshaft, which ultimately propels the vehicle forward. Inline engines, particularly in the inline-four configuration, are favored for their simplicity and their capacity to provide dependable performance across various vehicle types.

Types of Inline Engine

Inline engines are classified by the number of cylinders they possess. Here are the primary types of inline engines:

Inline-2 Engine (Parallel Twin):

Having two cylinders organized in a straight line, this type is prevalent in small motorcycles and scooters, providing simplicity and efficiency.

Inline-3 Engine (Inline Triple):

Merging compactness with balanced power, this engine is commonly seen in motorcycles and compact cars. It is a flexible option for lighter vehicles.

Inline-4 Engine:

Highly favored for midsize cars, motorcycles, and light trucks, this configuration offers outstanding efficiency. Its compact structure makes it a preferred choice for numerous manufacturers.

Inline-5 Engine:

Preferred by companies like Audi and Volvo, this engine achieves a unique balance between power and smooth operation, appealing to those who desire both performance and sophistication.

Inline-6 Engine:

Renowned for its remarkable balance and smooth performance, this engine is typically found in luxury cars and sports sedans, delivering a seamless driving experience accompanied by substantial power.

Inline-8 Engine:

Although infrequent today, this setup was historically significant in high-performance cars and classic luxury vehicles, providing remarkable power and status during its era.

Larger inline engines, such as Inline-10, Inline-12, or Inline-14, are primarily utilized in heavy-duty functions like trains and ships.

Applications of Inline Engine

Inline engines are adaptable and found in various industries:

Passenger Vehicles:

Inline-4 and Inline-6 engines are prevalent in sedans, hatchbacks, and luxury vehicles like BMW and Jaguar.

Motorcycles:

Compact Inline-2 and Inline-3 engines dominate this category due to their favorable balance of power and size.

Trucks and SUVs:

Inline engines offer the strength and torque necessary for towing and heavy loads.

Aviation:

Inline engines have been modified for light aircraft, taking advantage of their efficiency and compactness.

Industrial Machinery:

Inline engines drive machinery like generators and pumps. They are frequently used in equipment owing to their reliability and low upkeep.

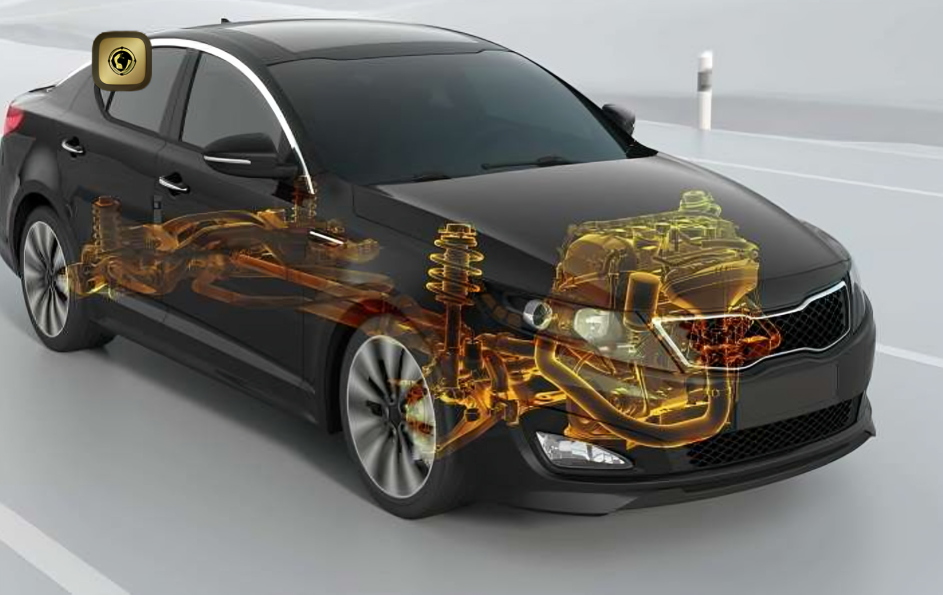

Components of Inline Engine

The efficiency of the inline engine is attributed to its well-coordinated parts, each serving an important function:

Housing:

The outer shell that encloses and safeguards all engine components.

Pistons:

Situated within the cylinders, pistons move vertically to generate power from fuel combustion.

Cylinders:

House the fuel-air mixture, where combustion takes place to create energy.

Crankshaft:

Transforms the pistons’ up-and-down movement into rotational movement, propelling the wheels.

Camshaft:

Coordinates the opening and closing of valves, facilitating the four-stroke cycle.

Connecting Rods:

Connect pistons to the crankshaft, efficiently transferring energy.

Advantages and Disadvantages

Some benefits and drawbacks of inline engines are:

Advantages

- Simplicity:

Straightforward design simplifies construction and maintenance. - Compact Size:

Smaller dimensions are suitable for compact vehicles and motorcycles. - Cost-Effective:

Low production and maintenance costs render it economical. - Balanced Weight:

Provides good stability and handling for vehicles. - Lightweight:

Ideal for uses that require minimal weight. - Single Cylinder Head:

Lowers complexity and cost compared to V-type engines.

Disadvantages - Overheating Issues:

Cooling can be less efficient in comparison to other engine layouts. - High Centre of Gravity:

This might affect vehicle stability. - Noise:

Can generate more noise when navigating rough terrain. - Limited Rigidity:

Lacks the structural strength of V6 or V8 engines, especially in larger vehicles.

Conclusion

Inline engines represent a fundamental aspect of automotive engineering, providing efficiency, simplicity, and versatility across numerous applications. For vehicle owners, conducting regular maintenance and securing the proper motor insurance is crucial. While third-party car insurance is the minimum legal requirement, acquiring a comprehensive plan is recommended to safeguard your vehicle.

Leave A Comment